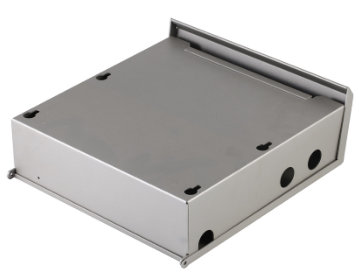

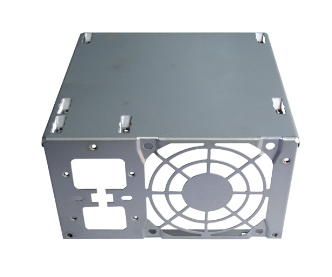

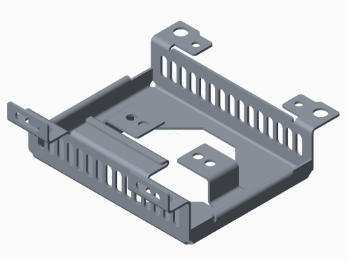

What Is Sheet Metal Fabrication?

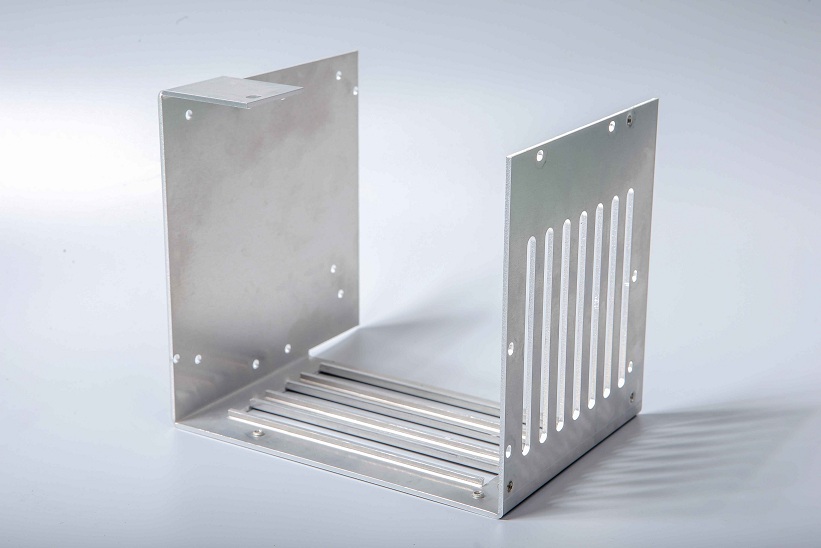

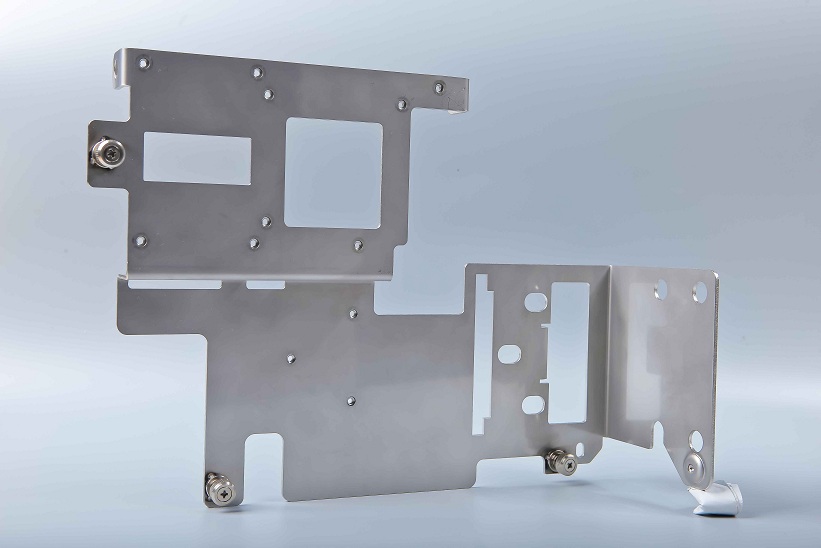

Sheet metal fabrication is one of the traditional manufacturing process. Usually the material is steel or aluminum. In the process, the material will be turned into metal structures or products, by cutting, punching, folding and assembling. Sheet metal can be bent, cut or stretched into a variety of shapes, which is usually made by cutting and burning the metal material.

At ZH, we can supply cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU) brass, copper, beryllium copper, aluminum sheet (6061, 6063,etc.), aluminum profiles, stainless steel (mirror surface, brushed surface, matte surface). We can give professional advice according to product usage and cost.

Search

Search