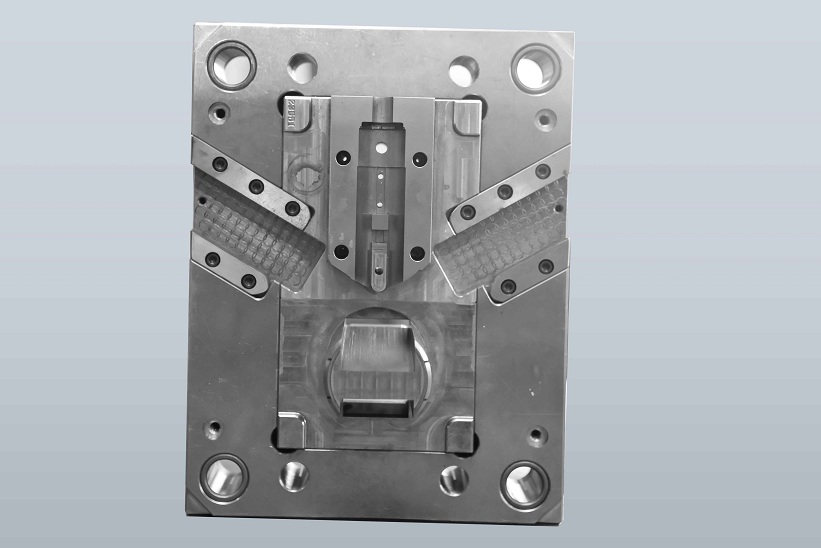

What Is Injection Molding?

Injection molding(also called plastic injection molding) is a manufacturing process start from 1940s. The advantages of injection molding are fast production speed, high efficiency, automatic operation, various designs, shapes from simple to complex, sizes from large to small, and accurate product dimensions. Widely used in daily necessities, consumer electronics, automotive industry, and aerospace, etc.

At ZH, we provide injection molding service from tools making to mass production including finishing service. We can produce 20 to 10,000,00+ parts in all kinds of plastic material.

Search

Search