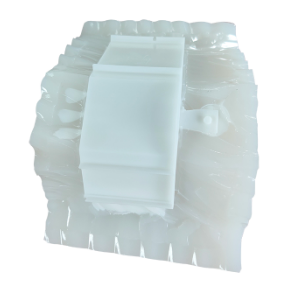

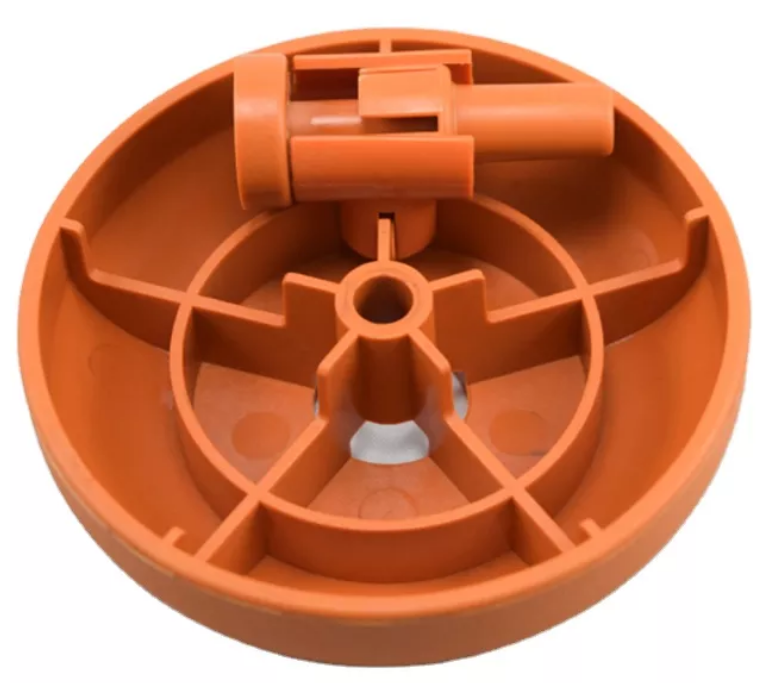

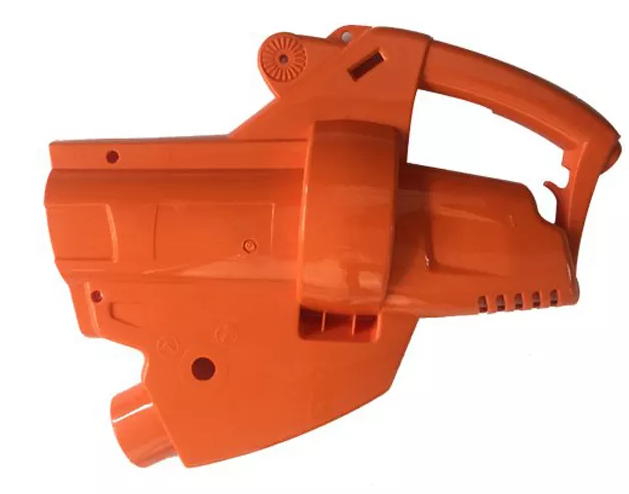

What Is the Vacuum Casting?

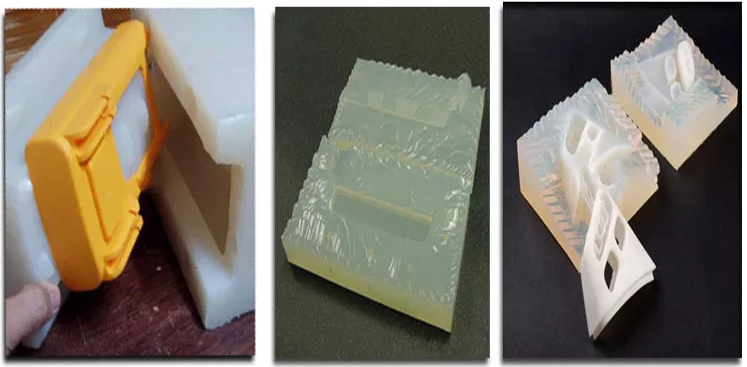

Vacuum Casting is a copying technique used for the production of small series of functional plastic parts. Using two-component polyurethanes and silicone molds, Vacuum Casting is known for its fast production of high-quality prototypes or end-use products.

Search

Search